Yazaki Europe – Octopus Reporting

Octopus Reporting provides users with a quick overview of the product model of the physical wiring system. The system makes the most important information about a wiring harness available centrally and uniformly to all process partners in the company. In this way, it provides important input for various internal processes such as costing, change evaluation or work preparation - successfully and reliably since 2007.

Project environment

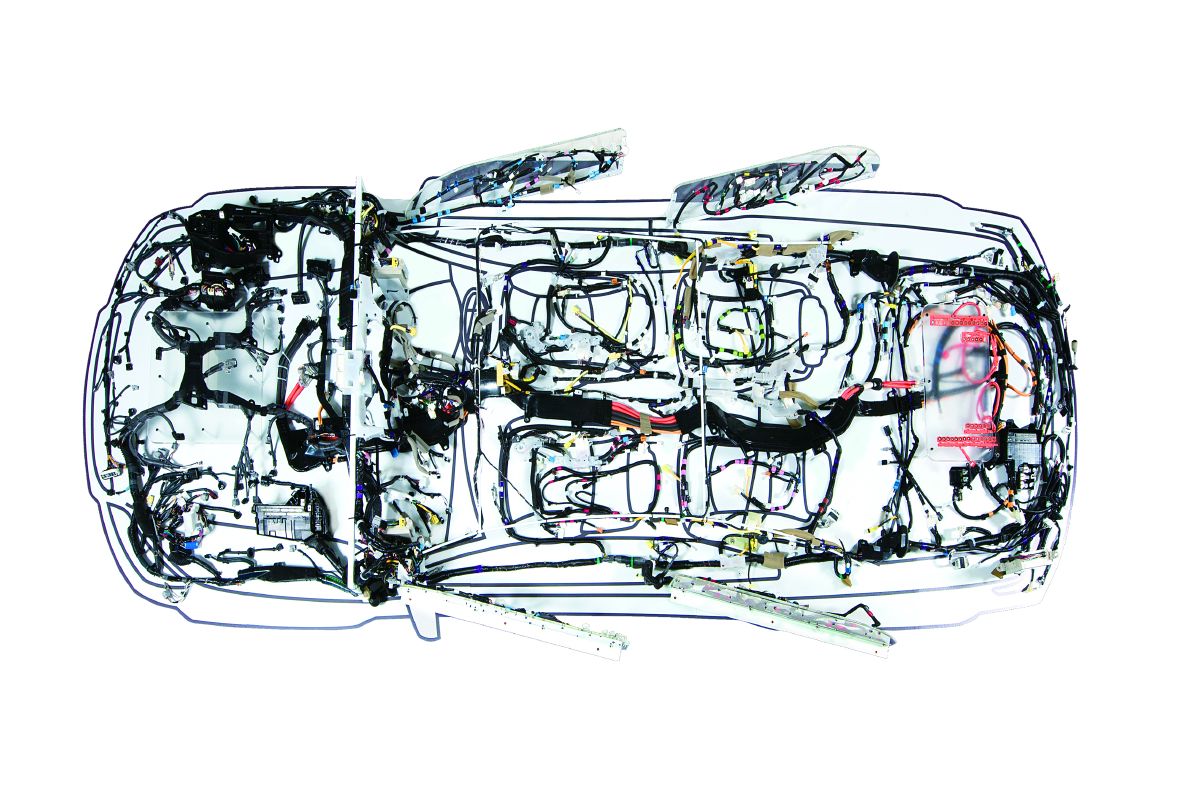

In today’s vehicles, the physical wiring system is the most complex and most varied single component supplied. Without consistent digitization, the development, production and logistics of this product in the process chain would be virtually inconceivable. Starting in 2006, the major German OEMs introduced the KBL standard for digital product specification at the process interface to their wire harness suppliers. This meant that, in addition to the classic wiring harness drawing, a standardized digital product model of the wiring harness was available for the first time for subsequent processes. With the Octopus Reporting web application, this information supplied by the OEM can be managed centrally and evaluated efficiently for follow-up processes.

The challenge of the physical wiring system. Maintaining an overview here is crucial. ©Yazaki Europe

Customer benefits

Many processes require specific information on the “wiring harness” product, for example on parts or connection lists, plug or fuse assignments. Octopus provides such information centrally and uniformly as PDF or Excel reports. In this way, employees can independently, quickly and easily obtain exactly the information they currently need about a wire harness in a defined development status. Since Octopus stores and manages the underlying data internally in a structured manner, it is always clear on what basis information was provided. Additional information can be retrieved by the user at any time later, if required. The continuous optimization and adaptation of the “wiring harness” product is part of everyday life in wiring system development. Therefore, a comparison function in a system such as Octopus must not be missing, of course. Based on different views, the user can get a quick overview of the differences between two development statuses and perform a change evaluation.

Our contribution

Individual software solutions in the field of physical wiring system development are our specialty. Thanks to our extensive experience in the processes of the various stakeholders and our involvement in the design of the relevant standards KBL and VEC, we find sensible and pragmatic solutions for our customers to improve the digitization of existing processes and close gaps. As a full-service provider, we advised and supported our customer Yazaki on Octopus Reporting from the initial project idea onwards and subsequently took over both the design and implementation of the system. Since the go-live in 2007, we have continuously taken care of maintenance and support as well as the implementation of new requirements.

Customer review

Ein kleines Tool mit großem Nutzen: Octopus begleitet uns seit 2007. Es bietet eine schnelle und unkomplizierte Ansicht aller Kundendaten. Wir profitieren nicht nur vom technischen IT-Wissen sondern vor allem von der Fachkompetenz auf dem Gebiet des VDA-Standards KBL sowie der Kenntnisse der kundenspezifischen Dialekte der deutschen OEMs. Octopus bietet uns eine zuverlässige Grundlage für unsere Alltagsarbeit, daher schätzen wir dieses praktische Tool